How 3D Printing Will Optimise Your Next Pair of Running Shoes

This technology of the future is already starting to arrive.

This technology of the future is already starting to arrive. – By Tim Newcomb

Your favourite running shoe may not look like your neighbour’s all that much longer. Shoe manufacturers are putting focus far beyond the glue and stitching in sneaker construction to create customisable footwear that molds to every individual runner.

What’s Happening Now

Using “selective laser sintering,” a 3D-printing process that constructs components of a shoe one layer at a time, rather than the traditional model of cutting or injecting foam, companies can engineer the structure of a shoe – starting with the outsole and moving into the midsole – to create unique models from the ground up. It also allows them to dial in a custom fit more quickly, because they can tweak a prototype in a matter of hours, rather than the months-long process of building and shipping shoes from factories in Asia. Nike used the method to speed up production of prototypes in order to go through several dozens of iterations of track spikes for elite athletes such as Allyson Felix, as she was preparing for the Rio de Janeiro Olympics.

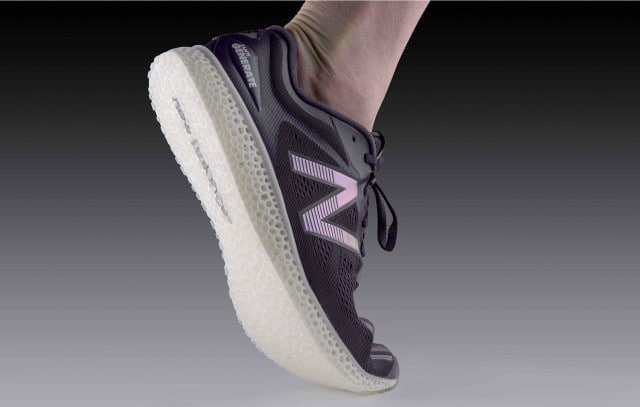

New Balance has done the same to fine-tune track spikes for its athletes. But spikes, of course, don’t fulfill the needs of most runners. In 2016, the company released the Zante Generate, the first commercially available running shoe with a full-length (but not customised) 3D-printed midsole, though it made and sold only 44 pairs.

Adidas wasn’t far behind. Late last year, it released a limited edition 3D Runner with a 3D-printed midsole and heel counter ($333). While both of these early models came in standard sizes and were heavier and stiffer than their EVA counterparts, they offered proof of concept of a new way of thinking about design and materials.

The Future

When will runners be able to slip their feet into custom-built shoes, made to fit the curves of their feet and their unique biomechanical needs? For now, the major players are tight-lipped on specifics, but all indicators suggest we’ll see more options from more brands this year – customised footwear for individual runners, not just elites.

In the second half of 2017, Adidas is bringing this level of customisation to the U.S. with its Speedfactory, a production facility in the US. Its goal is to deliver cutting-edge manufacturing and produce more shoes with “advanced complexity in colour, materials, and sizes” for U.S.-based retailers and consumers. “The vision of Speedfactory is about making customised and personalised footwear for all people,” says Ben Herath, vice president of global design. “We’re bringing shoe manufacturing closer to the people and speeding up the manufacturing time.”

Under Armour has similar ambitions with its now-open Lighthouse design and manufacturing centre in Baltimore, USA, another facility intended to speed up shoe manufacturing and open customisation opportunities. Without releasing exact details or timing of products, the company promises an expansion of its 3D footwear platform.

New Balance, too, continues to work on specialised manufacturing, but has not yet released timing for its plan to have both a customised running shoe based on biomechanical data and a way for it to happen in real time.

For regular runners, Nike teamed with technology giant Hewlett-Packard in 2016 for the “immediate challenge” of creating a cushioning system from 3D-printed materials, says Tony Bignell, vice president of footwear innovation. While the results have proven too stiff and heavy so far, “we believe that the next frontier is to deliver a 3D material for cushioning, at scale, to athletes around the world.” The timetable for delivering a product that can be comfortably run in is currently not known.

HP also teamed up with insole manufacturer Superfeet to roll out 3D-printed insoles in the first quarter of 2017 across a handful of specialty running stores. The technology allows customers to get a 3D scan of their feet, and uses that data to not only suggest current running shoes that will fit best but also to build custom-fit Superfeet insoles and recovery slides. Via a kiosk that scans an individual foot and uses pressure-plate data to mine metrics for the recommendation and customization, the early process will take a couple of weeks to produce the insole, something Superfeet hopes to have down to hours as the technology evolves.

So what’s the upshot of all this innovation? The era of customisation is upon us and within the next couple of years everybody’s feet will be treated like an elite’s!

READ MORE ON: gear running-shoes shoes